Product Information Quick View

· Equipment condition

brand new

· Customizable Situation

yes

· Price range

negotiable

· Primary application field

ship

description

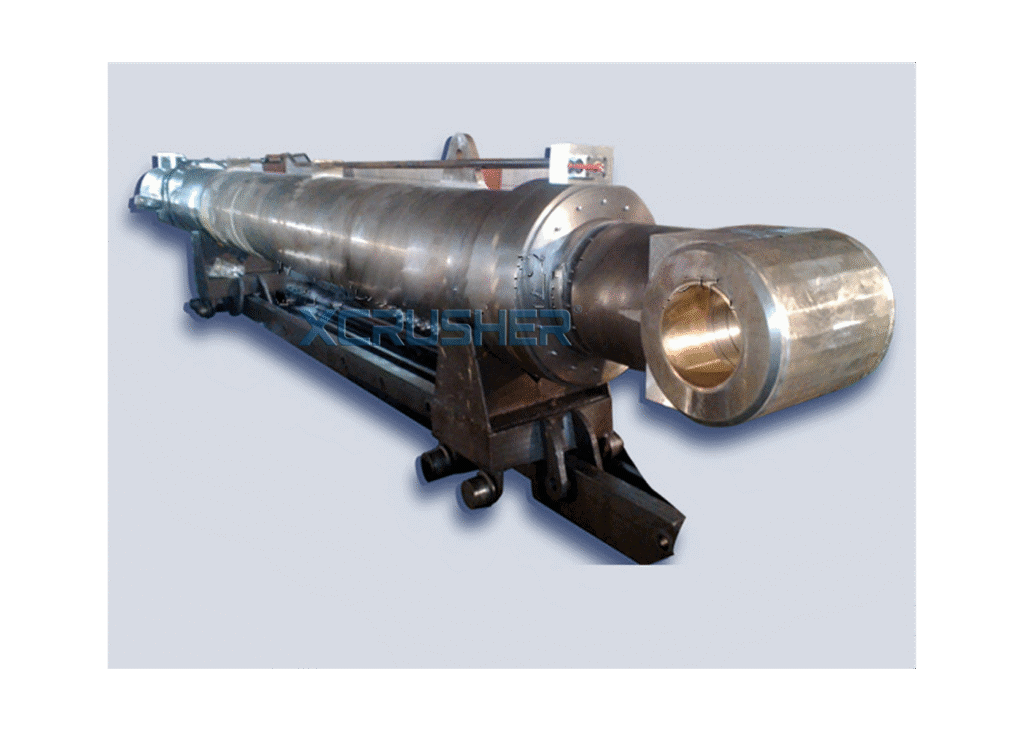

Main Materials of Hydraulic Cylinder: Cylinder body made of 45# steel, piston rod made of 45# bar material, etc.

Hydraulic Cylinder Seal Brands: U.S. MPI Fluoro-rubber, Swedish SKF PTFE, Austrian Polyurethane

Hydraulic Cylinder Models: 250/160-1200*1880, etc.

Hydraulic Cylinder Types: Hydraulic Foldable Hatch Cover Cylinder, Long Stroke Hydraulic Cylinder

Cylinder Installation Methods: End ring mounting, Mid ring mounting

Hydraulic Cylinder Applications: Hydraulic systems for hatch covers of 10,000-ton container vessels, foldable hatch cover hydraulic systems, hydraulic systems for hatch covers of 10,000-ton bulk carriers. CNMS Machinery is one of the first companies certified by China Classification Society (CCS). The main hydraulic cylinders for ships include: hatch cover hydraulic cylinders, cargo handling hydraulic cylinders, marine steering gear cylinders. Our company has long provided hatch cover cylinders, cargo handling cylinders, etc., to shipyards in Fujian, Zhejiang, and other regions.

Mandatory Inspection and Certification – The Only Certificate Number in the Country

Due to the harsh marine environment, where hydraulic cylinders for ships often operate in humid and highly corrosive conditions, the material quality of the cylinder body and the quality of the seals are especially critical. CNMS Machinery Hydraulic Cylinder Factory, as a company certified by the China Classification Society (CCS), considers product quality to be the lifeblood of the company and has always placed a high emphasis on quality. After years of validation and support by major shipyards in Fujian, Zhejiang, and other regions, the quality of our hatch cover hydraulic cylinders is excellent, with an extremely low failure rate and long service life.

The inner bore of the cylinder is processed through deep hole boring for rough and fine machining, followed by a rolling process. The surface roughness of the cylinder tube can reach 0.4. The rolling process forms a hardened surface layer on the inner bore, which greatly reduces the friction between the piston and the cylinder tube, making it less prone to damage. This effectively enhances the sealing performance of the oil seal and significantly improves the service life of the hydraulic cylinder.

The piston rod undergoes tempering treatment (HB260-280). After rough and fine machining, the surface is polished and then coated with 0.03-0.05mm of hard chrome. It is further polished with specialized polishing equipment to achieve a surface finish of 0.2. This treatment significantly reduces friction, preventing damage to the cylinder tube, and greatly enhances the service life of the hydraulic cylinder.

As a China Classification Society (CCS) certified company, every hatch cover hydraulic cylinder (hatch cover hydraulic cylinder) manufactured by CNMS Machinery Hydraulic Cylinder Factory must undergo strict testing and inspection by affiliated enterprises of the classification society. Only after passing the inspection is the product issued with a certificate number and certification.

Key Advantages

Double Chrome Plating for Strong Acid and Alkali Corrosion Resistance

After B260-280 treatment, an additional layer of 0.01-0.03mm white chrome and 0.03-0.05mm hard chrome is applied, followed by repeated polishing to ensure that the piston rod surface achieves a smoothness of 0.2.

High Fatigue Strength, Safe and Reliable

Based on years of use across various companies, performance tests over 724365 operation have shown that the product is stable, reliable, and guaranteed in quality. It is safe and dependable!

Honing Process Creates a Superior Finish

The cylinder tube’s inner bore undergoes deep hole boring for rough and fine machining, followed by honing. The surface roughness of the cylinder tube reaches 0.4, and the inner bore forms a uniform grid of honing marks, enhancing the quality exponentially!

Alloy Steel Forged Cylinder Tubes

Large forged alloy steels, such as 9Cr2, 9Cr2.0, and 9Cr2W, undergo a series of treatments including forging, preheating, high-temperature processing, thermal insulation, passivation, and high toughness treatment.

Specifications

Common Hatch Cover Hydraulic Cylinder Models & Specification Reference Table

(Model Selection Guide for Hatch Cover Hydraulic Cylinders)

| ΦD | ΦA | φd | ΦE | M | M1 | 2-Φd | B | SR | I | L4 | F | G |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 200 | 245 | 140 | 120 | M27x1.5 | M27x2 | GE120ES | 130 | 130 | 700 | 520 | 280 | 460 |

| 220 | 270 | 140 | 120 | M27x1.5 | M27x2 | GE120ES | 130 | 135 | 700 | 520 | 300 | 480 |

| 250 | 295 | 160 | 120 | M27x1.5 | M27x2 | GE120ES | 130 | 150 | 700 | 520 | 320 | 500 |

| 280 | 340 | 180 | 140 | M27x1.5 | M27x2 | GE140ES | 160 | 170 | 720 | 550 | 360 | 540 |

| 300 | 350 | 180 | 140 | M27x1.5 | M33x2 | GE140ES | 160 | 170 | 720 | 550 | 380 | 570 |

| 340 | 400 | 200 | 140 | M27x1.5 | M33x2 | GE140ES | 160 | 200 | 750 | 580 | 430 | 630 |

| 360 | 426 | 200 | 160 | M27x1.5 | M33x2 | GE160ES | 180 | 210 | 750 | 580 | 450 | 650 |

Double-Acting Hatch Cover Hydraulic Cylinder Model and Specification Comparison Table

| Model | Bore (D/mm) | Rod Diameter (d/mm) | Pressure (MPa) | Thrust Force (N) | Pull Force (N) | Max Stroke (mm) | Max Flow Rate (L/min) |

|---|---|---|---|---|---|---|---|

| JG1-40 | 40 | 22 | 16 | 19698 | 13720 | 400 | 9 |

| JG1-50 | 50 | 28 | – | 30772 | 21070 | 500 | 14 |

| JG1-63 | 63 | 35 | – | 48804 | 33810 | 630 | 22 |

| JG1-80 | 80 | 45 | – | 78792 | 53990 | 800 | 35 |

| JG1-100 | 100 | 55 | – | 123088 | 85848 | 1000 | 55 |

| JG1-125 | 125 | 70 | – | 192374 | 132104 | 1250 | 86 |

| JG1-160 | 160 | 90 | – | 315266 | 215600 | 1600 | 140 |

| JG1-200 | 200 | 110 | – | 492548 | 343686 | 2000 | 220 |

| JG1-220 | 220 | 125 | – | 595742 | 493368 | 2200 | 260 |

| JG1-250 | 250 | 140 | – | 769594 | 528318 | 2500 | 340 |

| JG1-280 | 280 | 160 | – | 965006 | 649838 | 2800 | 420 |

| JG1-320 | 320 | 200 | – | 1261260 | 862400 | 3200 | 546 |

| JG1-360 | 360 | 200 | – | 1595146 | 1102784 | 3600 | 690 |

| JG1-400 | 400 | 220 | – | 1969048 | 1373568 | 4000 | 850 |

| JG1-1-100 | 100 | 70 | 25 | 192276 | 98098 | 1000 | 55 |

| JG1-1125 | 125 | 90 | – | 300468 | 148568 | 1250 | 86 |

| JG1-1-160 | 160 | 110 | – | 492450 | 259602 | 1600 | 140 |

| JG1-1-200 | 200 | 140 | – | 769300 | 392294 | 2000 | 220 |

| JG1-1-20 | 220 | 160 | – | 930853 | 438501 | 2200 | 258 |

| JG1-1-250 | 250 | 180 | – | 1201970 | 578886 | 2500 | 340 |

| JG1-1-280 | 280 | 200 | – | 1507828 | 738528 | 2800 | 418 |

| JG1-1-320 | 320 | 220 | – | 1969408 | 1038555 | 3200 | 546 |

Application industries & materials

Hatch Cover Hydraulic Cylinder Functions

As a critical component of ship deck machinery, the hatch cover hydraulic system is primarily used for the opening and closing of cargo holds on large-scale bulk carriers. The corresponding hatch cover hydraulic cylinders are integral parts of this system. Each type of hatch cover system requires specific models of hydraulic cylinders. Regardless of the design, hydraulic hatch covers play a key role in withstanding container loads as well as environmental loads such as wind and rain.

With the increasing size of container ships, hatch cover structures have become more complex, and performance requirements are more demanding. The hatch cover is the main structure that bears container loads and weather-related loads. Under such multi-load conditions, the hydraulic hatch cover structure must meet not only strength and stiffness standards but also buckling strength requirements. These large and heavy hatch covers—especially those on 10,000+ DWT vessels—require immense power to perform smooth opening and closing actions. This powerful hydraulic force is precisely what the hatch cover hydraulic cylinders deliver.

Applications of Hatch Cover Hydraulic Cylinders

Hatch cover hydraulic cylinders are primarily used in the following systems:

-

Hydraulic systems for container ship hatch covers

-

Hydraulic systems for folding hatch covers

-

Hydraulic systems for bulk carrier hatch covers

Notably, the export-grade 17,600 DWT multipurpose bulk carrier built for Sweden uses a hatch cover system composed of folding open-deck hatch covers, hoisted tween-deck hatch covers, lift-off storage hatch covers, and hoisted grab hatch covers, including hydraulic hinge-type covers. These systems require extremely high standards in cylinder quality.

The hydraulic folding hatch cover system is one of the most widely used structural types on bulk carriers worldwide. It is also one of the key product lines for CNMS Machinery, which manufactures a high volume of hatch cover hydraulic cylinders to meet this demand.